The ABS is a sophisticated system comprising several components that work together to prevent wheel lock-up. Understanding these parts and recognizing when they need replacement is key to keeping the system operational.

Core ABS Components

- Wheel Speed Sensors: These monitor each wheel’s rotational speed, sending data to the ABS control module. They’re essential for detecting potential lock-up.

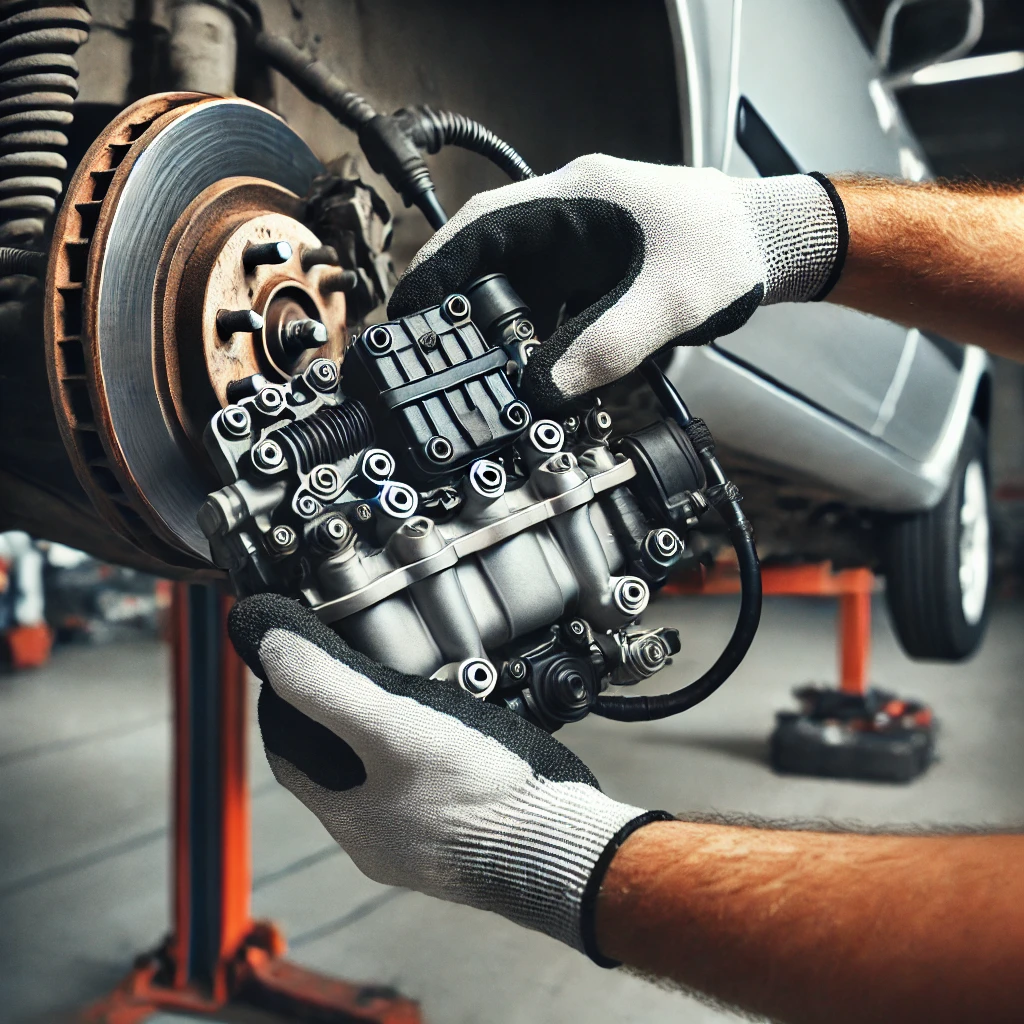

- ABS Control Module: The system’s brain, it processes sensor data and controls brake pressure adjustments.

- Valves: Positioned in the brake lines, these regulate fluid pressure to each wheel, opening and closing rapidly to prevent lock-up.

- Pump: This restores brake pressure after the valves release it, ensuring consistent braking power.

- Brake Fluid: Transfers force from the brake pedal to the wheels; its condition affects ABS performance.

Signs They Need Replacement

- Wheel Speed Sensors: Replace if damaged by debris or corrosion. Symptoms include an illuminated ABS light or erratic braking.

- ABS Control Module: Less common to fail, but electrical issues can necessitate replacement. Look for ABS not engaging or activating unnecessarily.

- Valves and Pump: Wear from frequent use may require replacement if braking feels delayed or less responsive.

- Brake Fluid: Replace every 2-3 years to avoid contamination, which can cause a spongy pedal or reduced braking efficiency.

Maintenance Tips

Regular diagnostics, often triggered by an ABS warning light, can pinpoint failing components. Professional inspection is recommended to ensure accurate repairs.

Key Takeaway: Knowing the roles and failure signs of ABS components helps you address issues before they compromise safety.